Hygienic Belting Range

Positive drive belts (or sprocket driven belts) combine the benefits of modular belts and mono-material conveyor belts without the drawbacks of hygiene issues:

Positive drive belts (or sprocket driven belts) combine the benefits of modular belts and mono-material conveyor belts without the drawbacks of hygiene issues:

Optimised functionality

- No risk of slippage

- Assembly without tensioning reduces effort on the mechanical components

- No need for tensioning devices

- Lightweight belt

- Silent operation

- Excellent resistance to tears and abrasion

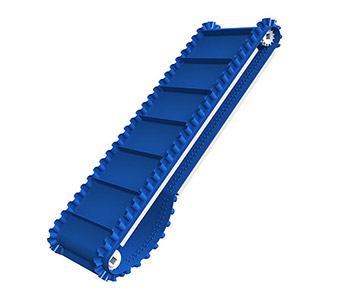

- Moulded teeth are part of the material itself

Maximum levels of hygiene

Maximum levels of hygiene

- CE – FDA food-grade compliance

- Mono-material is waterproof and rot-proof

- Easy and quick cleaning

- Resistant to chemicals

- Option to add a scraper if required

Decrease in sanitary risks

- Decreased risk of bacterial growth

- No fabric threads eliminate the risk of product contamination

- No risk of contamination with broken modules

- Simple conveyor design means better hygiene

Reduction in operating costs

- Increased life cycle

- Quick and effective cleaning without dismantling the conveyor

- Decrease in water consumption and detergent products

- Reduction in maintenance costs

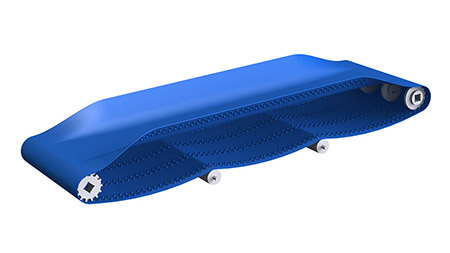

The perfectly smooth upper surface of the POSITIVE BELT makes belt cleaning easy and helps to maintain optimum hygiene.

Highly resistant to abrasions and tears, the POSITIVE BELT offers extended durability.

Assembly without tensioning limits stress/strain on the conveyor components.

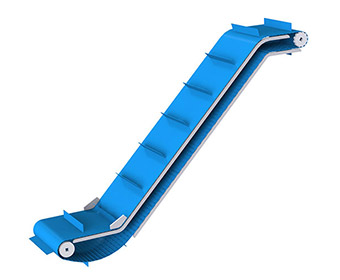

Profiles and sidewalls can be welded to the belt to meet handling needs.

The combination of double row teeth and sprockets with a central disk ensures that the belt is perfectly guided.